Get Legacy Foundry and Metal Casting Electronic Components Online

Keeping your production running starts with having the right parts on hand. We provide foundry and metal casting electronic components that keep your critical systems operating smoothly.

Keeping your production running starts with having the right parts on hand. We provide foundry and metal casting electronic components that keep your critical systems operating smoothly.

Whether you are maintaining older automation equipment or repairing specialized casting machinery, we make it easy to find what you need online.

Summit Electronics specializes in sourcing obsolete electronics and legacy electronic components for foundry operations. We connect you to a global supply network so you can replace outdated parts without the cost of replacing entire systems.

Frequently Asked Questions About Our Legacy Components

Q: What types of obsolete electronics can you supply?

A: We source everything from PLC modules and sensors to induction furnace controls and integrated circuits, helping you replace parts that are no longer in production.

Q: How do I know if you have the component I need?

A: You can upload your bill of materials or part numbers directly through our website. Our team will check inventory and global supplier networks for availability.

Q: Do you test components before shipping?

A: Yes. Every part undergoes testing and inspection to confirm it meets performance standards before it leaves our facility.

Q: Can you get older equipment that has no direct replacement parts?

A: Yes. We specialize in sourcing foundry and metal casting electronic components for older and custom-built systems that require specialized or discontinued parts.

Types of Legacy Components We Supply

Control and Automation Components

Automation is at the heart of modern foundries. We supply programmable logic controllers (PLCs) to manage furnace operation, material handling, and mold cycles. Human-machine interfaces (HMIs) give operators a user-friendly way to control automated systems, while industrial computers handle data acquisition and process control.

We also provide sensors, including thermocouples, pressure sensors, flow sensors, and proximity sensors, to monitor casting conditions. Servo motors and drives allow precise movement of robotic systems and material handling equipment.

Power and Distribution Components

Foundry operations demand reliable power distribution. We supply variable frequency drives (VFDs) to control motor speed and torque, as well as power supplies that keep electronic control systems running. Circuit breakers, rectifiers, and current transformers protect equipment and maintain stable operation during high electrical loads common in foundry environments.

Specialized Foundry Equipment Electronics

Metal casting requires specialized machinery. We supply control boards and electronics for induction furnaces, robotic handling systems, and automated molding and core-making machines. These parts allow for precise melting, mold formation, and material handling, all critical for production efficiency.

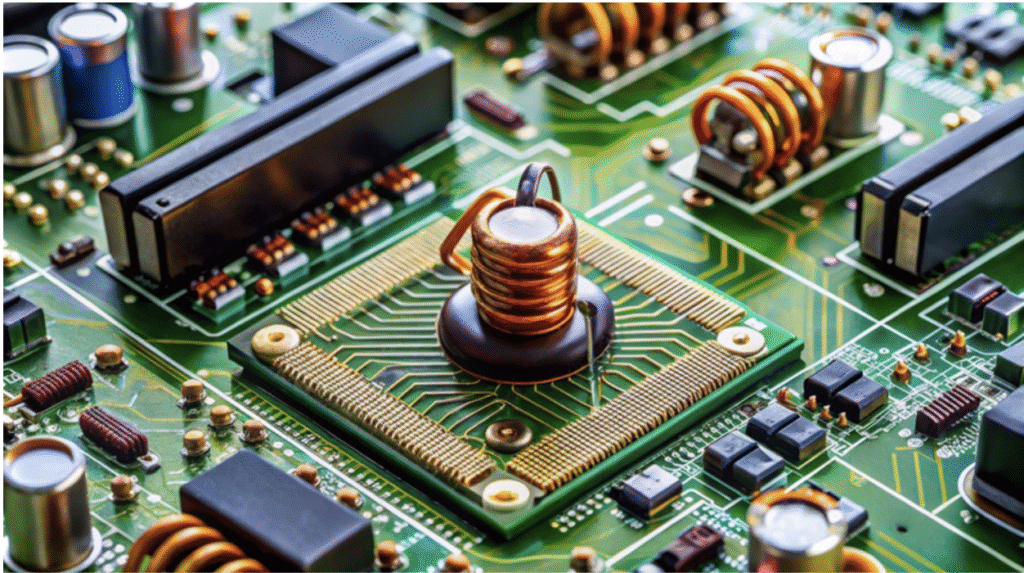

Basic Electronic Components for Foundries

In addition to control system modules, we source basic electronics like resistors, capacitors, diodes, transistors, and integrated circuits (ICs). These components are essential for keeping both legacy and newer equipment operational. We also supply connectors and crystal oscillators that support timing and signal management in casting systems.

Legacy Components Are Critical to Maintain Production

Many foundries rely on systems designed decades ago but still perform reliably. The challenge comes when these systems need parts no longer in regular production. Having access to foundry and metal casting electronic components designed for older systems helps avoid costly downtime and extends the lifespan of existing equipment.

Replacing entire systems is expensive and often unnecessary. By sourcing obsolete electronics, you can replace only what is needed, saving money and minimizing downtime. Legacy parts also support unique equipment like custom molding machines or specialized induction systems that may not have direct replacements on the market.

Electronics in Metal Casting Operations

Foundries use a wide variety of electronics to control processes and ensure quality. Sensors monitor temperature, pressure, and flow rates to maintain precise conditions. PLCs manage automated systems, sending control signals to actuators and robotic equipment.

Power supplies and frequency converters provide consistent electrical energy and allow precise control of motors for conveyor systems, pumps, and material-handling equipment.Induction heating systems also rely on electronic control circuits to melt and hold metal, ensuring consistent material quality.

These components are often unique to the industry and require specialized knowledge to source. Summit Electronics understands these needs and focuses on providing parts that other suppliers may no longer carry.

Our Sourcing Advantage

Summit Electronics has built a strong global network to locate parts that are no longer available through regular distribution channels. Every part we supply undergoes testing and inspection to verify quality. Our team specializes in legacy electronic components and knows how they fit into complex foundry operations.

This knowledge allows us to respond quickly, deliver accurate quotes, and ship parts on schedule. We help keep production moving with minimal downtime, even when older systems are involved.

How to Order Online

- Search or upload your part list through our website.

- Request a fast quote from our sourcing team.

- Place your order and track shipment status from start to finish.

Get Expert Help

If you are unsure about part compatibility or cannot find a specific module, contact us. Our team has experience identifying and sourcing hard-to-find items, from basic circuit components to specialized induction furnace controllers.

We will keep your systems powered and productive. Contact us today or request a quote. Click here or give us a call toll-free at (800) 226-6960.