If you manage legacy equipment in wind farms, outdoor industrial drives, or rooftop HVAC units, you know the dread of a deep freeze. You press the start button on a frigid morning, and… silence. Or worse, smoke.

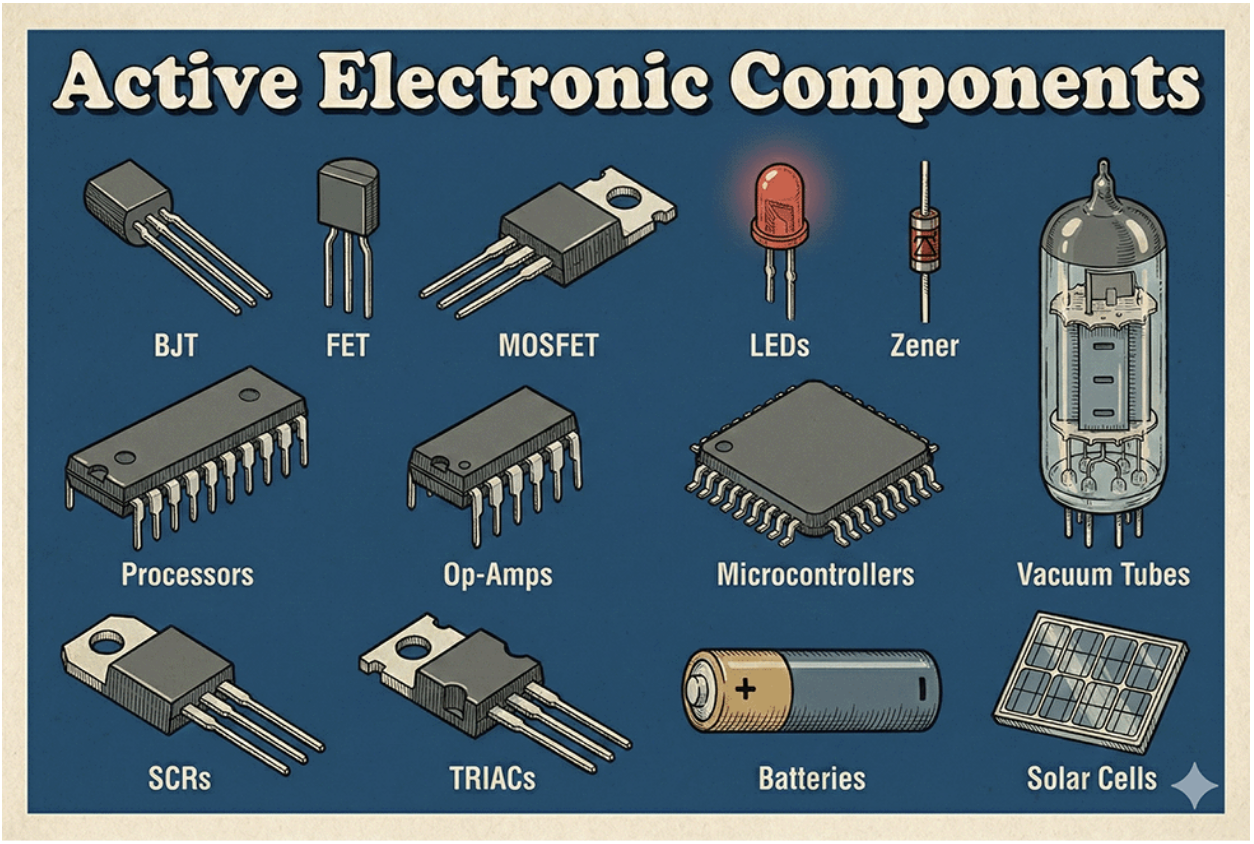

At Summit Electronics, we spend a lot of time helping engineers find replacements for parts that failed during these exact “cold start” scenarios. While we specialize in stocking obsolete and hard-to-find semiconductors—from IGBTs and SCRs to legacy MOSFETs and Power Rectifiers—we believe the best repair is understanding why the failure happened in the first place.

It turns out, winter reliability isn’t just about “getting too cold.” It’s a violent battle of physics happening inside your silicon.

The Physics of the Freeze: Phonons vs. Carriers

To understand why your Integrated Circuits (ICs) or Transistors act differently in January than they do in July, we have to look at the atomic level.

As discussed in physics communities like Stack Exchange, two opposing forces are at play when a semiconductor freezes:

- The “Good” News (Reduced Scattering): At low temperatures, the atomic lattice vibrates less. These vibrations are called phonons. Fewer phonons mean fewer obstacles for electrons to crash into, theoretically improving conductivity.

- The “Bad” News (Carrier Freeze-Out): Semiconductors rely on thermal energy to kick electrons across the “band gap” so they can conduct electricity. When the temperature drops, fewer electrons have the energy to make that jump. This reduces the carrier concentration, often making the device harder to turn on or causing it to behave erratically.

When you try to “wake up” a dormant machine in sub-zero temps, you are forcing current through a device that is electrically “stiff.” IGBTs may require a higher gate threshold voltage to open the channel, and Thyristors (SCRs) often need a significantly higher gate trigger current to fire reliably.

If your control circuit was designed 20 years ago (and hasn’t been calibrated for a polar vortex), it might not provide that extra kick, causing misfires or partial turn-ons that generate damaging hot spots.

The Thermal Shock: The Real Killer

However, the biggest enemy isn’t the electrical shift—it’s the mechanical stress.

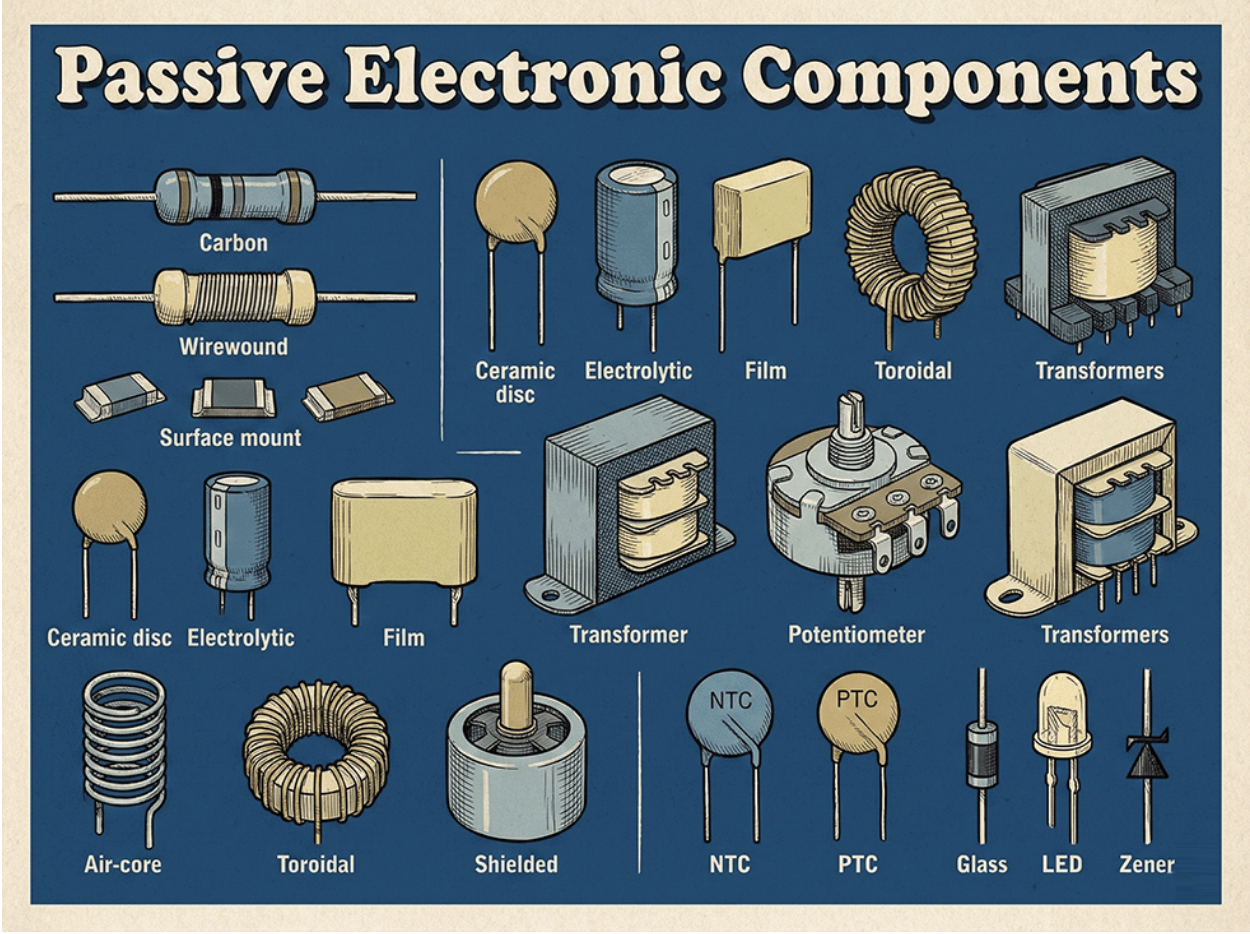

Power modules are sandwiches of different materials: silicon dies, copper baseplates, ceramic substrates, and solder. Each of these materials expands and contracts at a different rate.

When a power rectifier or module sits at -20°C and is suddenly hit with a full load current, it heats up rapidly. The internal components try to expand, but they are fighting each other. This rapid cold-to-hot transition is responsible for:

- Solder Fatigue: Cracks form in the solder layers, eventually disconnecting the chip from its heatsink.

- Bond-Wire Lift-off: The wires connecting the silicon chip to the terminals physically snap or detach.

Industry data suggests that nearly 20% of field failures are linked to this kind of thermal cycling. For obsolete equipment, this is catastrophic because the specific module that blew might not be in production anymore.

When Winter Wins, We Have Your Back

Modern systems might have “soft-start” algorithms to mitigate this, but older industrial machinery often just slams the power on. When that happens, and the capacitors blow or the voltage regulators fail, you need a replacement fast—not a 20-week lead time for a redesign.

At Summit Electronics, we specialize in the components that are keeping the world’s infrastructure running, even when the manufacturers have moved on. We stock:

- Discrete Semiconductors: Hard-to-find Diodes, Transistors, and MOSFETs.

- Power Modules: Heavy-duty IGBTs and Thyristors for industrial traction and power.

- Electromechanical: Relays and Switches that often freeze and stick in the cold.

- Legacy Tech: Electron Tubes and specific ICs for aerospace and defense applications.

Don’t let a cold snap permanently freeze your operations. Whether you are dealing with carrier freeze-out or simple solder fatigue, we likely have the part you need sitting on our shelf.

[Search Our Inventory of Obsolete Parts Now]

[Contact Our Team for a Custom Quote on Hard-to-Find Components]

Click here or give us a call toll-free at (800) 226-6960.